GSP SURF X FLUSH 2000 – PUR, Resin & Coating Remover

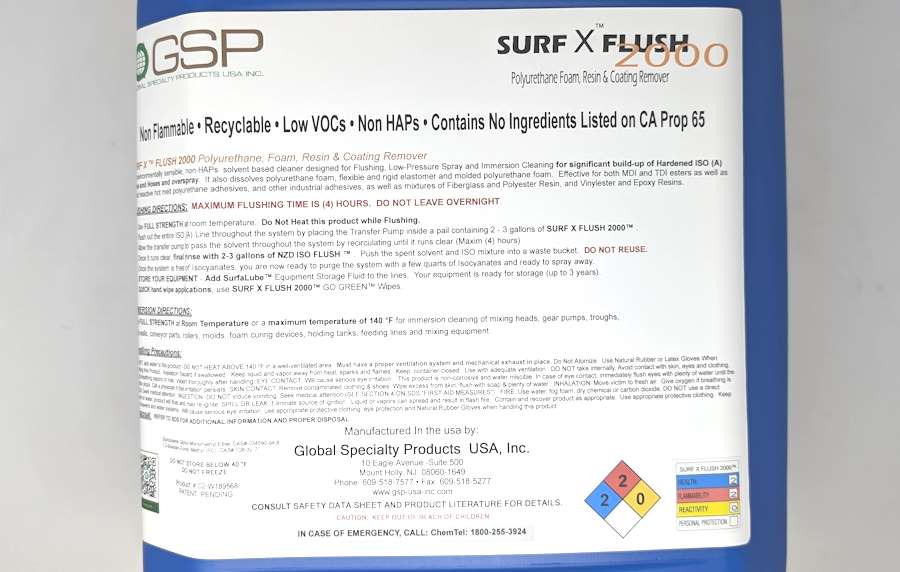

GSP SURF X FLUSH 2000 – Polyurethane Foam, Resin & Coating Remover

Part-#: GSP-SFX

Sizes: 5 gallon (18,9l) | 1 gallon (3,8l)

SURF X FLUSH 2000™ is a highly effective cleaning solution that can be used for Flushing, Low-Pressure Spray, and Immersion cleaning to remove build-up of Hardened ISO (A) lines and hoses, as well as over-spray. It has the ability to dissolve polyurethane foam, flexible and rigid elastomer, and molded polyurethane foam. This cleaning effectively cleans MDI and TDI esters, cured reactive hot melt, polyurethane adhesives, industrial adhesives, and mixtures of fiberglass and pol-yester resin, and vinylester and epoxy resin.

Original GSP Product.

*PURCRAFT is an authorized GSP distributor.

All mentioned product and company names, trademarks, registered trademarks or logos are the property of their respective owners and are used for identification purposes and for the determination of product compatibility only.

99,00 € – 369,00 €

excl. VAT plus shipping

Free Shipping – Get free shipping within the European Union on all orders of 1.000 € +

Secure Payment – We offer safe shopping guarantee

1-Year Warranty – We provide a one-year warranty on all our products

100% Satisfaction – Not happy with our products? We will do our utmost to solve the problem

GSP SURF X FLUSH 2000 - Polyurethane Foam, Resin & Coating Remover

Part-#: GSP-SFX

Sizes: 5 gallon (18,9l) | 1 gallon (3,8l)

Original GSP Product

SURF X FLUSH 2000™ is a highly effective cleaning solution that can be used for flushing, low-pressure spray, and immersion cleaning to remove build-up of hardened ISO (A) lines and hoses, as well as over-spray. It has the ability to dissolve polyurethane foam, flexible and rigid elastomer, and molded polyurethane foam. This cleaning agent effectively cleans MDI and TDI esters, cured reactive hot melt, polyurethane adhesives, industrial adhesives, and mixtures of fiberglass and pol-yester resin, and vinylester and epoxy resin.

Features & Benefits

- High Resin/Polymer loading

- Recyclable via vacuum distillation - Reduced disposal costs - Residue Free

- Replaces solvents such as NMP, BLO, Acetone, MEK, Methylene Chloride, PM Acetate and 1,1,1 Trichloroethane

- Low rate of evaporation

- Multi substrate - Safe of most Ferrous and non-Ferrous Metals

- Compatible and Non Corrosive on various metals, plastics, glass and ceramics

FLUSHING

- Use FULL STRENGTH at room temperature (Do Not Heat this product while Flushing).

- Flush out the entire ISO (A) Line throughout the system by placing the Transfer Pump inside a pail containing 2 - 3 gallons of SURF X FLUSH 2000.

- Allow the transfer pump to pass the solvent throughout the system by recirculating until it runs clear (Maxim (4) hours) Once it runs clear, do a final rinse with 2-3 gallons of NZD ISO FLUSH ™ . Push the spent solvent and ISO mixture into a waste bucket. DO NOT REUSE. MAXIMUM FLUSHING TIME IS (4) HOURS. DO NOT LEAVE OVERNIGHT.

- Once the system is free of Isocyanates, you are now ready to purge the system with a few quarts of Isocyanates and ready to spray away.

- STORE YOUR EQUIPMENT - Add SurfaLube™ Equipment Storage Fluid to the lines. Your equipment is ready for storage (up to 3 years).

IMMERSION

- Use FULL STRENGTH at room temperature or a maximum temperature of 140 °F for immersion cleaning of mixing heads, gear pumps, troughs, side walls, conveyor parts, rollers, molds, foam curing devices, holding tanks, feeding lines and mixing equipment.

If you want to store your hoses and equipment for longer terms, fill the equipment with GSP SurfaLube.

*PURCRAFT is proud to be an authorized GSP distributor.

All mentioned product and company names, trademarks, registered trademarks or logos are the property of their respective owners and are used for identification purposes and for the determination of product compatibility only.

Additional information

| Size | 5 gallon (18,9l), 1 gallon (3,8l) |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.